ARUM Wet & Dry Milling Machines – The Ultimate Milling Solution

Differentiated Dental CAD/CAM Products and Services

With the world's best technology, ARUM provides differentiated dental CAD / CAM milling machines and dental materials to laboratories all around, domestic and foreign. We are pleased to introduce our unrivaled technology through various lineup and superb partners from all over the world.

Introducing ARUM's CAD/CAM Milling Machine Lineup

Milling Machine Positioning Map

Milling Machine Models Comparison

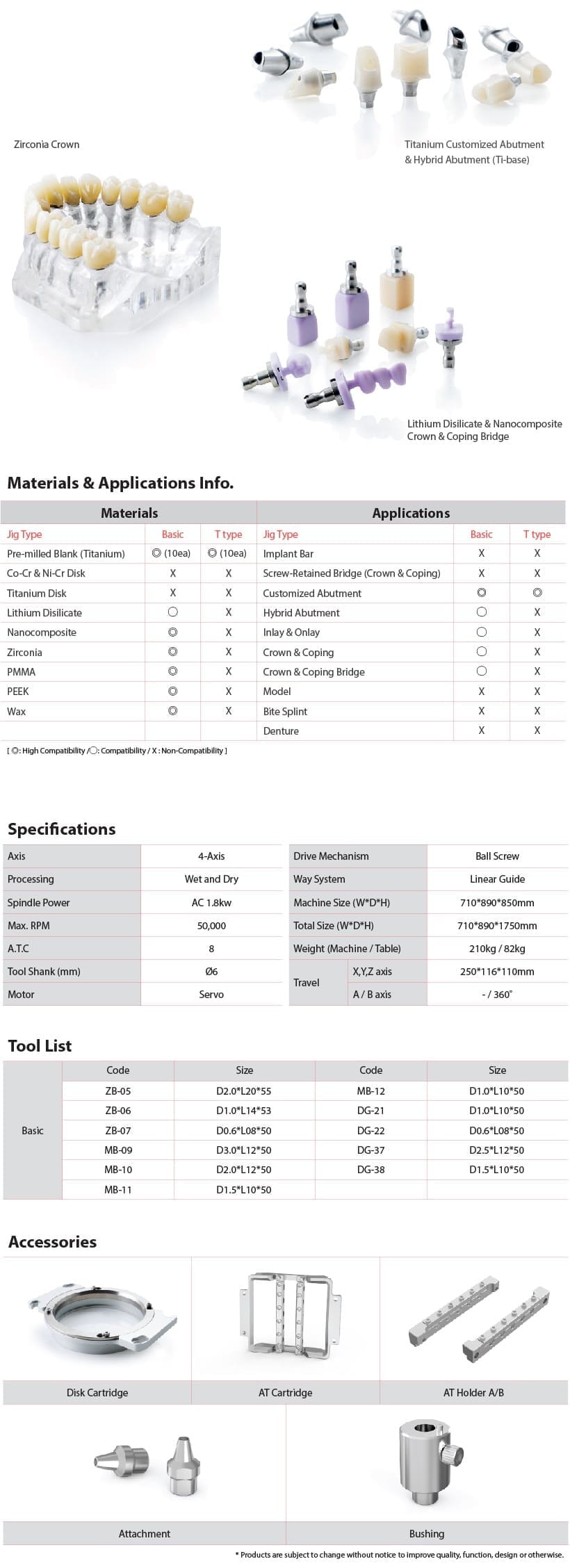

Milling Machine Model Specification:

- 5X-200

- 4X-100

- 5X-450 [450 Series]

- 4X-450 [450 Series]

- 5X-400

- 5X-300 / 5X-300D [300 Series]

- 4X-300 / 4X-300D [300 Series]

- 5X-300 Pro [300 Series] *NEW*

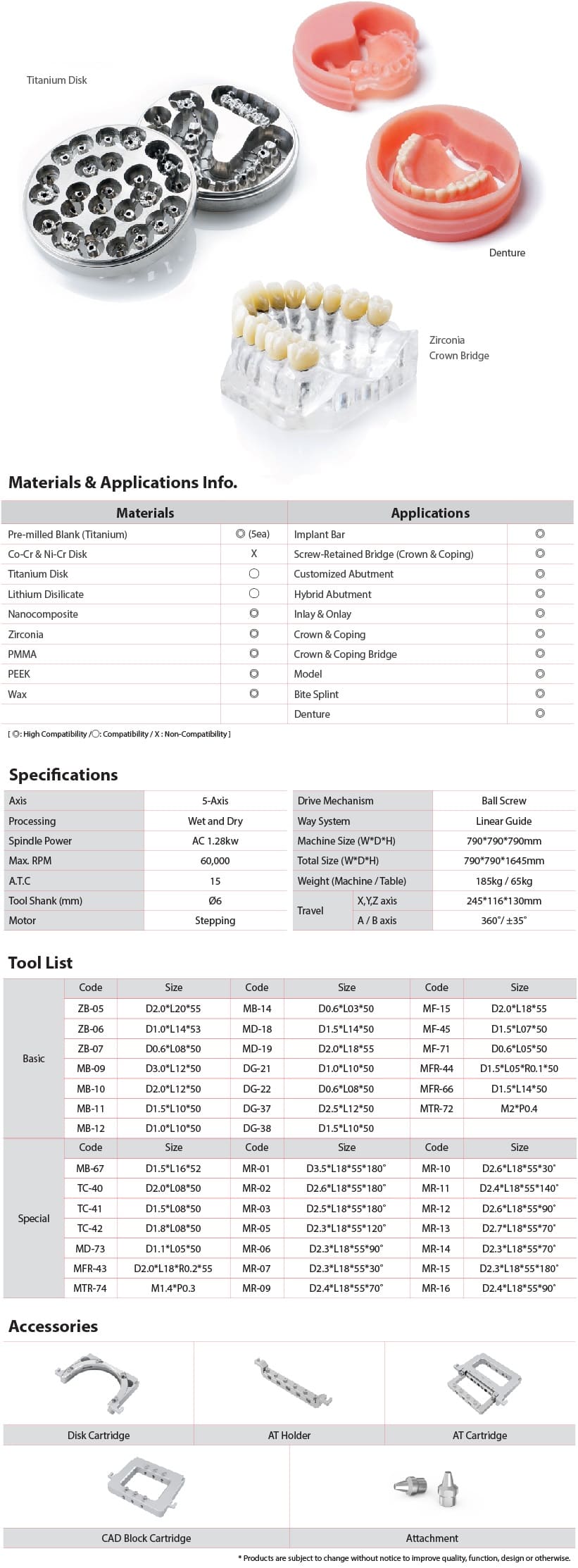

5X-200

Amazing milling power

Amazing milling power

With DC 3.0kw spindle, Servo Motor & Linear Guide, you can mill any dental material such as Titanium, Co-Cr, Pre-milled Blank, Zirconia, Lithium Disilicate, Nanocomposite, PMMA, PEEK, and WAX and more.

A standard of METAL milling

This machine can be compared with none of the metal milling machine. You can mill various shapes such as Implant Bar Bridge, Screw-retain Bridge, and Partial Framework using various materials such as Titanium, Co-Cr, and Ni-Cr, etc.

Based on unsurpassed metal milling capability and extensive know-how accumulated over many years, the excellence of our product has been proven in the global market.

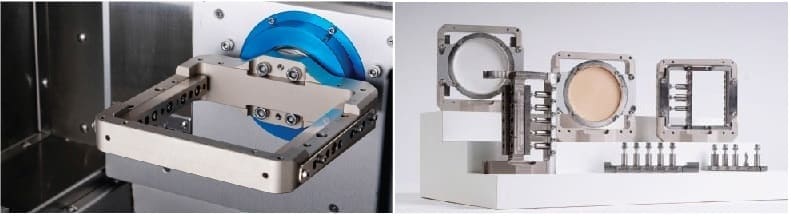

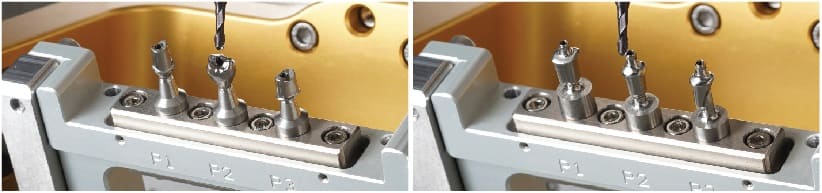

Mounting of 5 pre-milled blanks

With a function of mounting of 5 pre-milled blanks simultaneously. Also, you can product Customized Abutment without Connector with AT Holder.

Easy material replacement

As it is easy to replace Disk Cartridge, you can replace Disk quickly and easily and use materials economically. In addition to Disk, you can also exchange materials quickly such as Pre-milled Blank and CAD Block, etc.

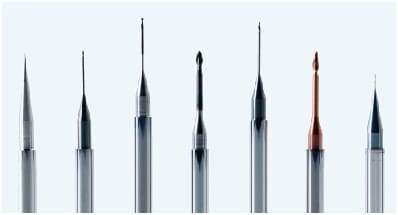

Special tool designed for perfection

The optimal tool designed to increase the completeness of milling. With use of ARUM's special tools such as Drill Tool, Reamer Tool, and Thread Tool, etc., you can achieve the best milling restoration.

↑ Scroll back to Milling Machine lineup ↑

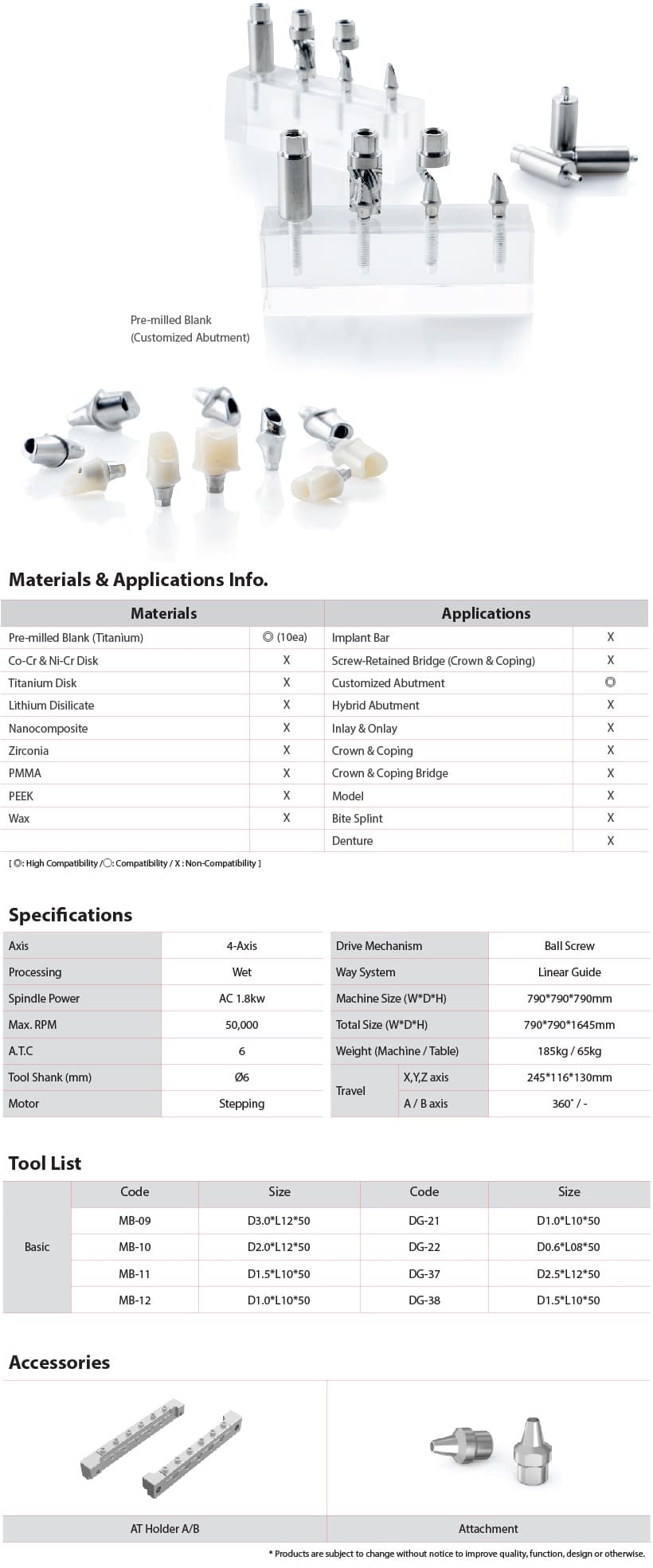

4X-100

Dedicated template for ARUM, Outcome of our extensive know-how

Dedicated template for ARUM, Outcome of our extensive know-how

Based on our extensive know-how accumulated over many years and various milling bases around the world, we provide the optimal dedicated template for ARUM for any case of Customized Abutment. This is ARUM’s unique asset that cannot be provided anywhere else.

From Disk to Pre-milled Blank

‘From Zirconia Disk milling using removable Disk Cartridge to Pre-milled Blank milling (10 pieces simultaneously)’ become possible.

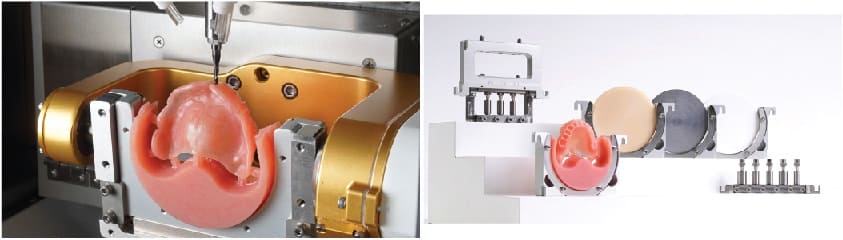

Cuff Side (Gingiva area) & Occlusal Side precision milling

With use of Attachment on Jig T Type, you can select the precision milling area according to the pre-milled blank mounting direction. Cuff Side (Gingival area) or Occlusal Side precision milling improves the completeness of Customized Abutment.

↑ Scroll back to Milling Machine lineup ↑

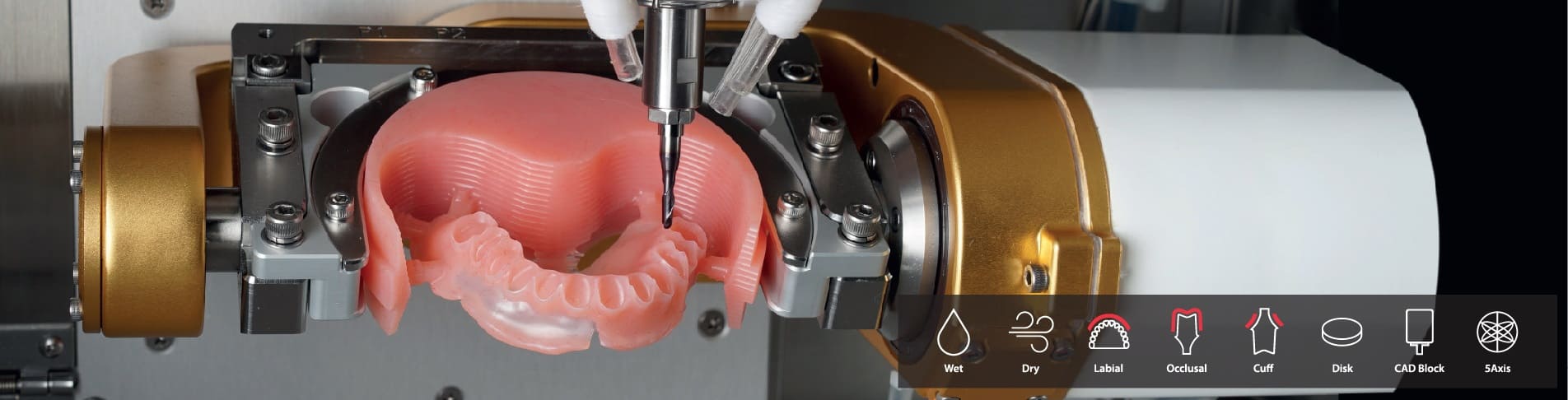

5X-450 [450 Series]

5X-450 for machining various prostheses at reasonable price

5X-450 for machining various prostheses at reasonable price

With use of open C type cartridge, you can precisely machine Labial Side (Buccal Side) and Under-Cut zone that requires additional machining.

With the amazing power of the best-in-class spindle AC 1.28kw, you can machine various shapes and materials such as Denture, Zirconia, CAD Block, and Titanium milled Bar. etc. (Except for Ni-Cr / Co-Cr Disk).

Differentiated round bar machining

You can machine Cuff Side (Gingival area), Occlusal Side, Connectorless, and Retention Groove in simple Top & Bottom Side milling using AT cartridge. Anyone can easily produce high quality Customized Abutment.

Machining with the removal of connector

You can mount 5 Pre-milled Blanks and machine Customized Abutment with removal of Connector using AT Holder and Attachment. The removal of Connector increases the degree of bonding with the upper prosthesis and reduces the workers’ post-stage works, improving work efficiency.

Maintenance of the best use conditions

With Auto Calibration Function, users can maintain the best condition of machine anytime. In particular, with Auto Calibration function by the location of Pre-milled Blank, you can produce high accuracy Customized Abutment.

↑ Scroll back to Milling Machine lineup ↑

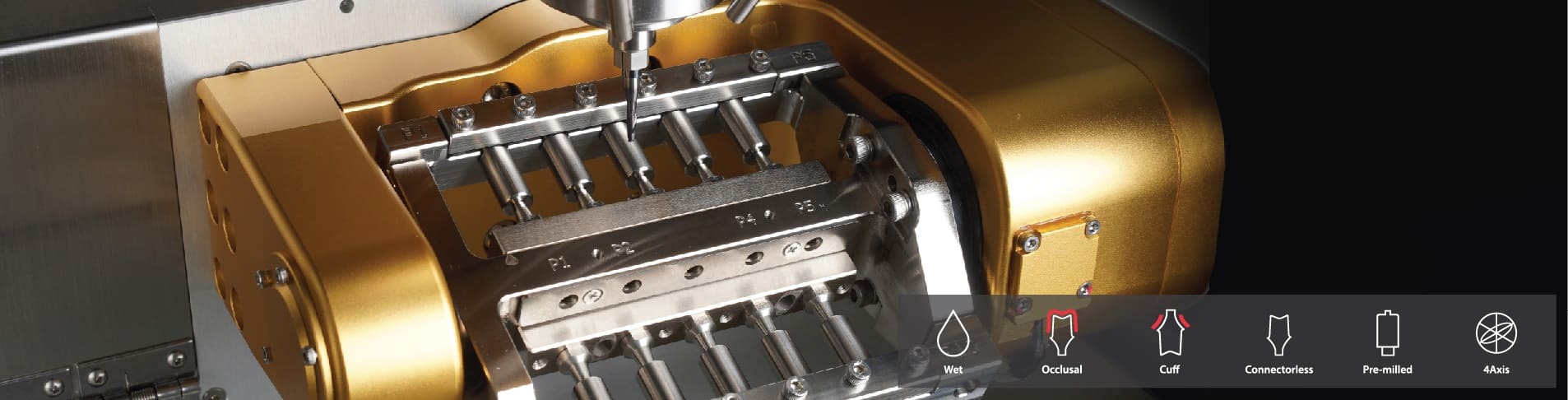

4X-450 [450 Series]

A standard of Pre-milled Blank machining

A standard of Pre-milled Blank machining

4X-450 is specialized in customized abutment milling and various pre-milled blank milling methods increases accuracy.

With a function of mounting of 10 pre-milled blanks simultaneously and a removable AT holder & Attachment allow you to precisely mill Cuf Side (gingiva area) and Occlusal Side.

Maintenance of the best use conditions

With Auto Calibration Function, you can maintain the best condition of machine anytime and anywhere. In particular, with Auto Calibration function by the location of Pre-milled Blank, you can produce high accuracy Customized Abutment.

↑ Scroll back to Milling Machine lineup ↑

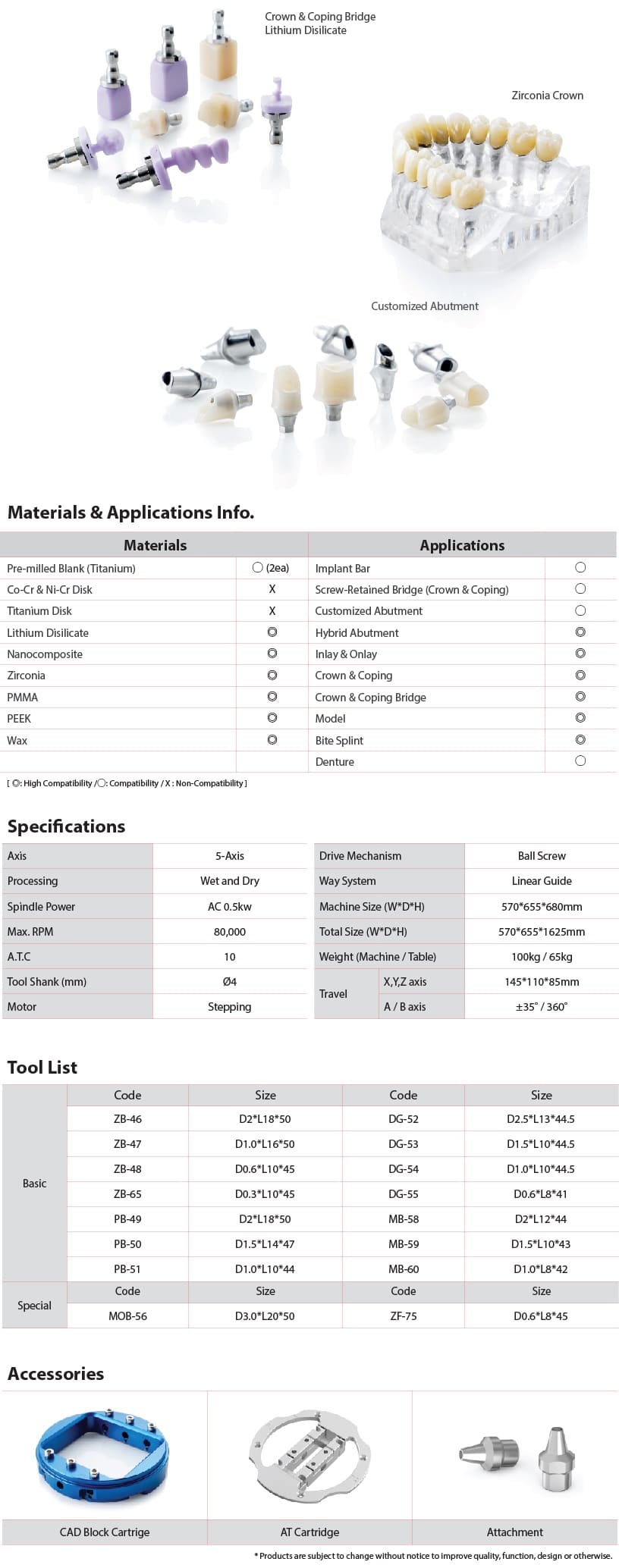

5X-400

Unrivaled grinding capability

Unrivaled grinding capability

With the adoption of a high RPM specialized spindle, this equipment boasts its unrivalled capability of grinding Lithium Disilicate (Glass Ceramic). We improved user convenience by applying the cartridge that can mount and machine up to 6 CAD Blocks (Lithium Disilicate, Nanocomposite), and the application of high-precision ball screws allows you to get high quality machining outputs.

Your reasonable choice

You can machine various materials from Zirconia Disk to CAD Block, Pre-milled Blank, and select between wet and dry machining. You can enjoy the maximum results at a reasonable price.

User-friendly environment

With Auto Calibration Function, you can maintain the best condition of machine anytime, anywhere. You can always see a certain level of machining. U.I design makes operation of equipment easy and simple.

Like natural teeth

Every patient wants a prosthesis that looks natural. With milling the grooved part precisely using ARUM's 0.3mm tool for Zirconia, you can reproduce the teeth that look natural.

↑ Scroll back to Milling Machine lineup ↑

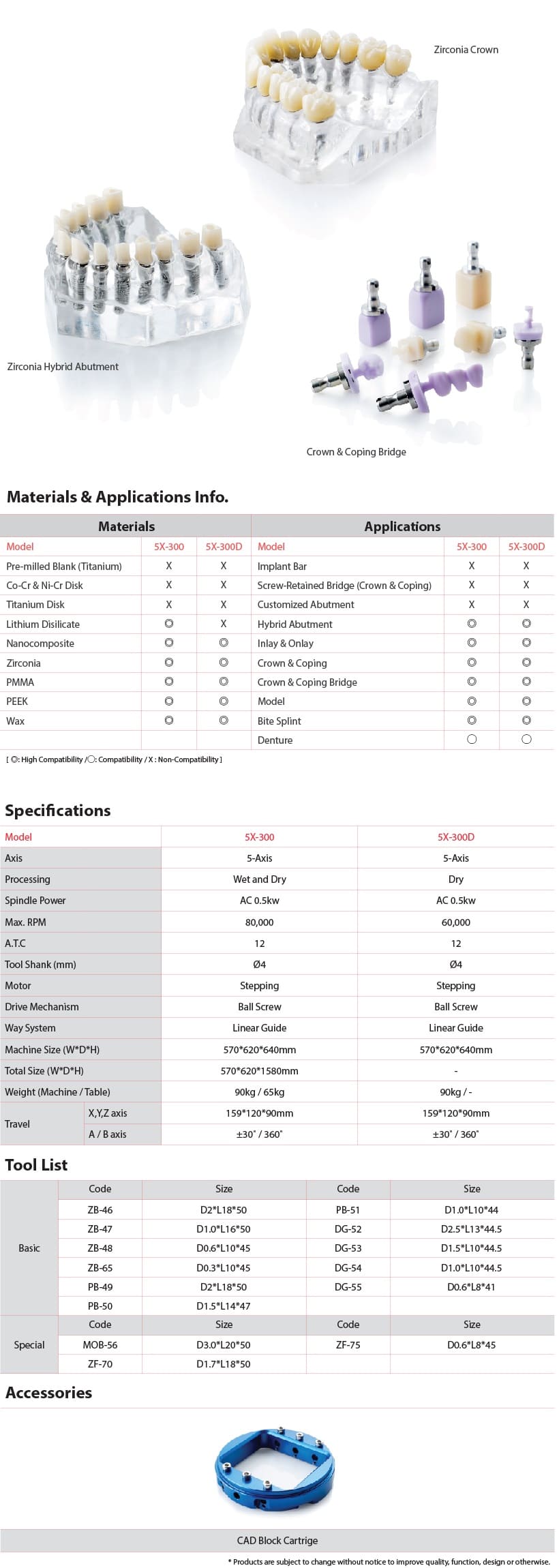

5X-300 / 5X-300D

Amazing grinding capability

Amazing grinding capability

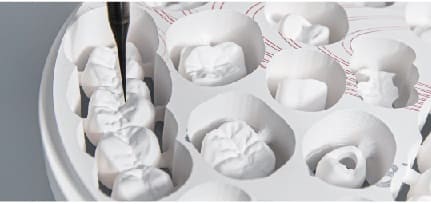

With the adoption of a high RPM spindle, 5X-300 boasts its unsurpassed capability of grinding Lithium Disilicate (Glass Ceramic). We improved user convenience by applying the cartridge that can mount and machine up to 6 CAD Blocks (Lithium Disilicate, Nanocomposite), and the of high-precision ball screws allows you to get high-quality milling outputs.

The beginning of a small change

With a small change of ‘7° Tilted Door’ to ensure user's viewing angle, you can clearly see the milling progress. With the door opening wide, you can secure enough work space to conveniently change materials and setting tools. In addition, the interior floor is inclined for convenient cleaning.

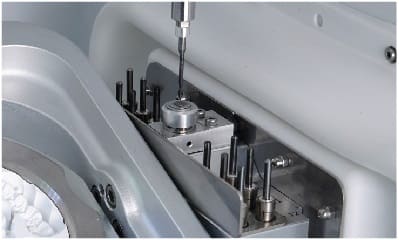

Device to automatically exchange 12 tools

With a 12-tool pocket, you can machine almost every material such as Zirconia, Lithium Disilicate, PMMA, PEEK, and WAX in just one setting, and the automatic tool change function allow you to use equipment without interruption.

User-friendly environment

With Auto Calibration Function, you can maintain the best condition of machine anytime, anywhere. You can always see a certain level of machining. U.I design makes operation of equipment easy and simple.

Like natural teeth

Every patient wants a prosthesis that looks natural. With milling the grooved part precisely using ARUM's 0.3mm tool for Zirconia, you can reproduce the teeth that look natural.

↑ Scroll back to Milling Machine lineup ↑

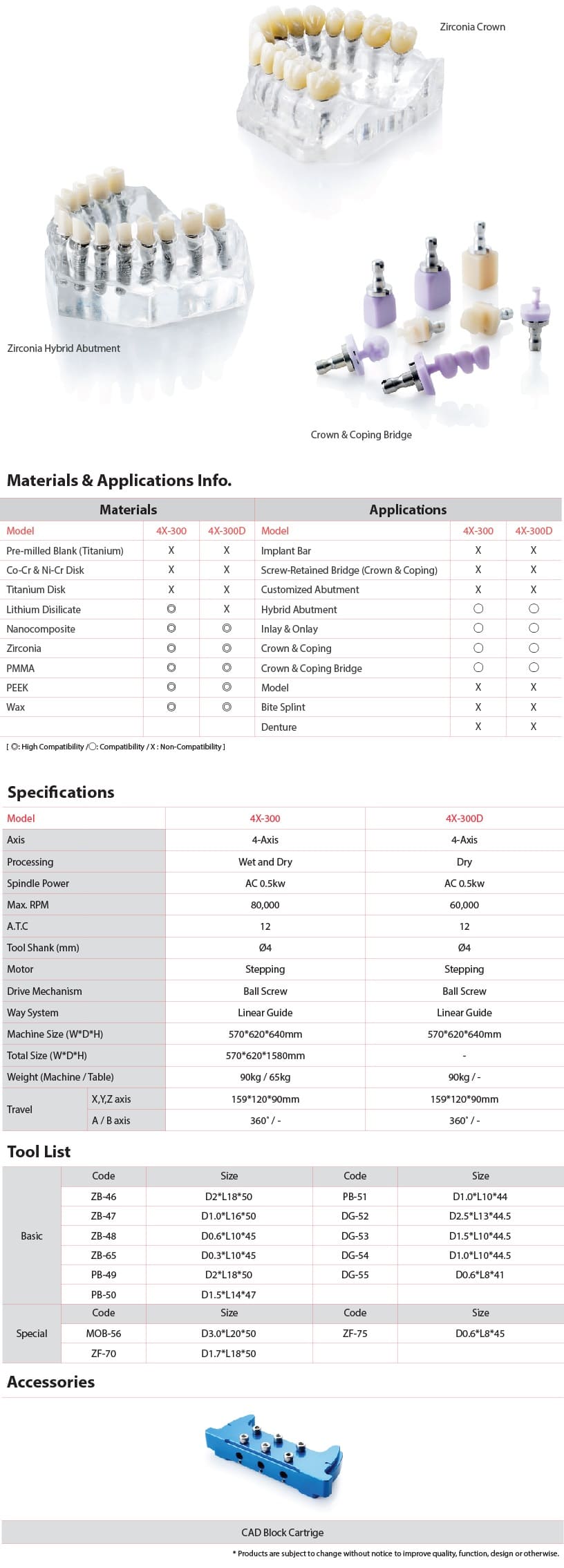

4X-300 / 4X-300D

Amazing grinding capability

Amazing grinding capability

With the adoption of a high RPM spindle, 4X-300 boasts its unsurpassed capability of grinding Lithium Disilicate (Glass Ceramic). We improved user convenience by applying the cartridge that can mount and machine up to 6 CAD Blocks (Lithium Disilicate, Nanocomposite), and the of high-precision ball screws allows you to get high-quality milling outputs.

The beginning of a small change

With a small change of ‘7° Tilted Door’ to ensure user's viewing angle, you can clearly see the milling progress. With the door opening wide, you can secure enough work space to conveniently change materials and setting tools. In addition, the interior floor is inclined for convenient cleaning.

Device to automatically exchange 12 tools

With 12 tool pockets, you can mill all materials, such as Zirconia, Lithium Disilicate, PMMA, PEEK, and WAX in just one setting, and the automatic tool change function allows you to use the machine without any interruption.

User-friendly environment

With Auto Calibration Function, you can maintain the best condition of machine anytime, anywhere. You can always see a certain level of machining. U.I design makes operation of equipment easy and simple.

Like natural teeth

Every patient wants a prosthesis that looks natural. With milling the grooved part precisely using ARUM's 0.3mm tool for Zirconia, you can reproduce the teeth that look natural.

↑ Scroll back to Milling Machine lineup ↑

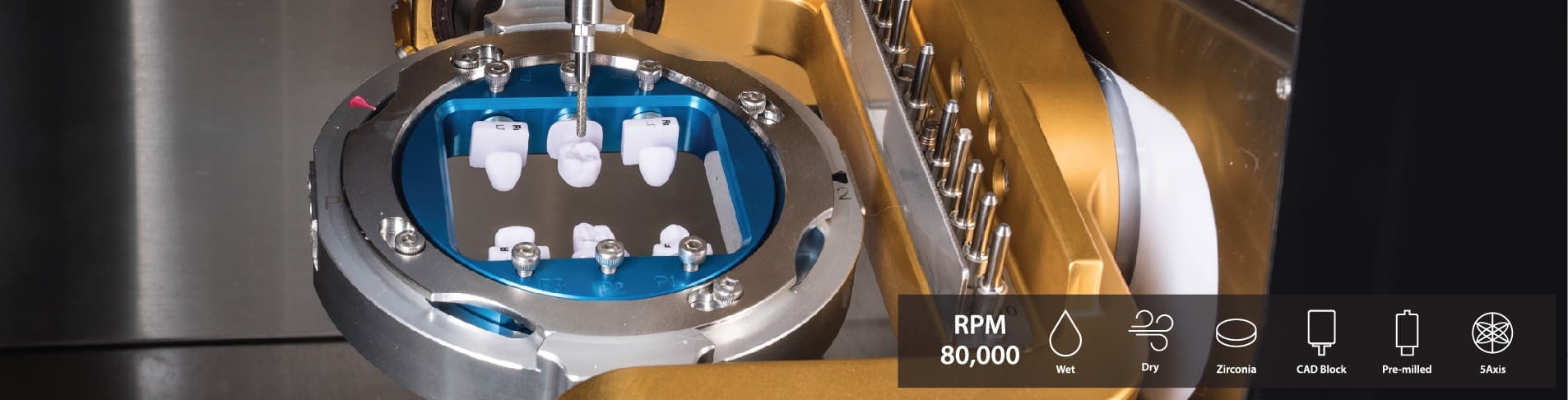

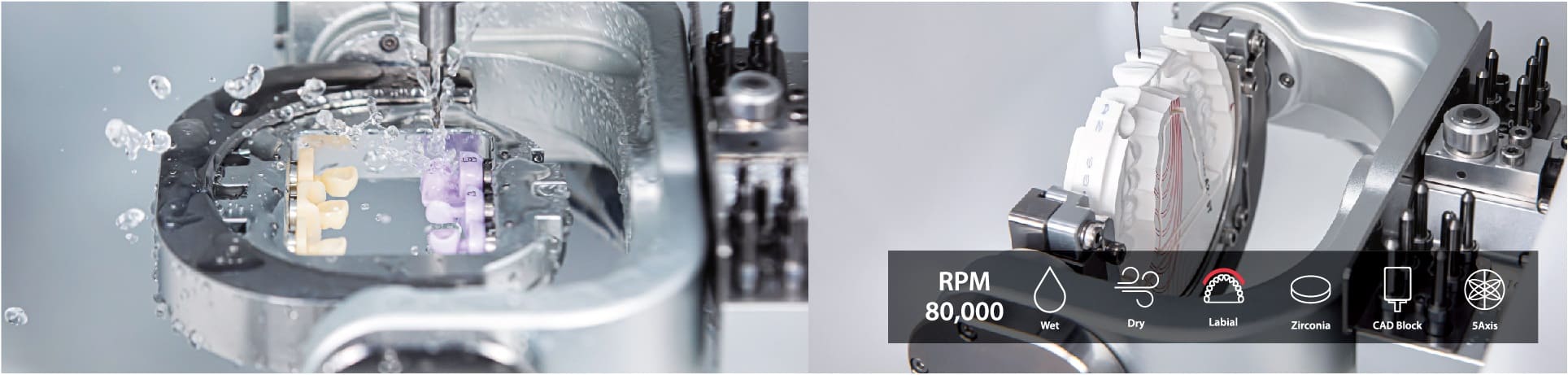

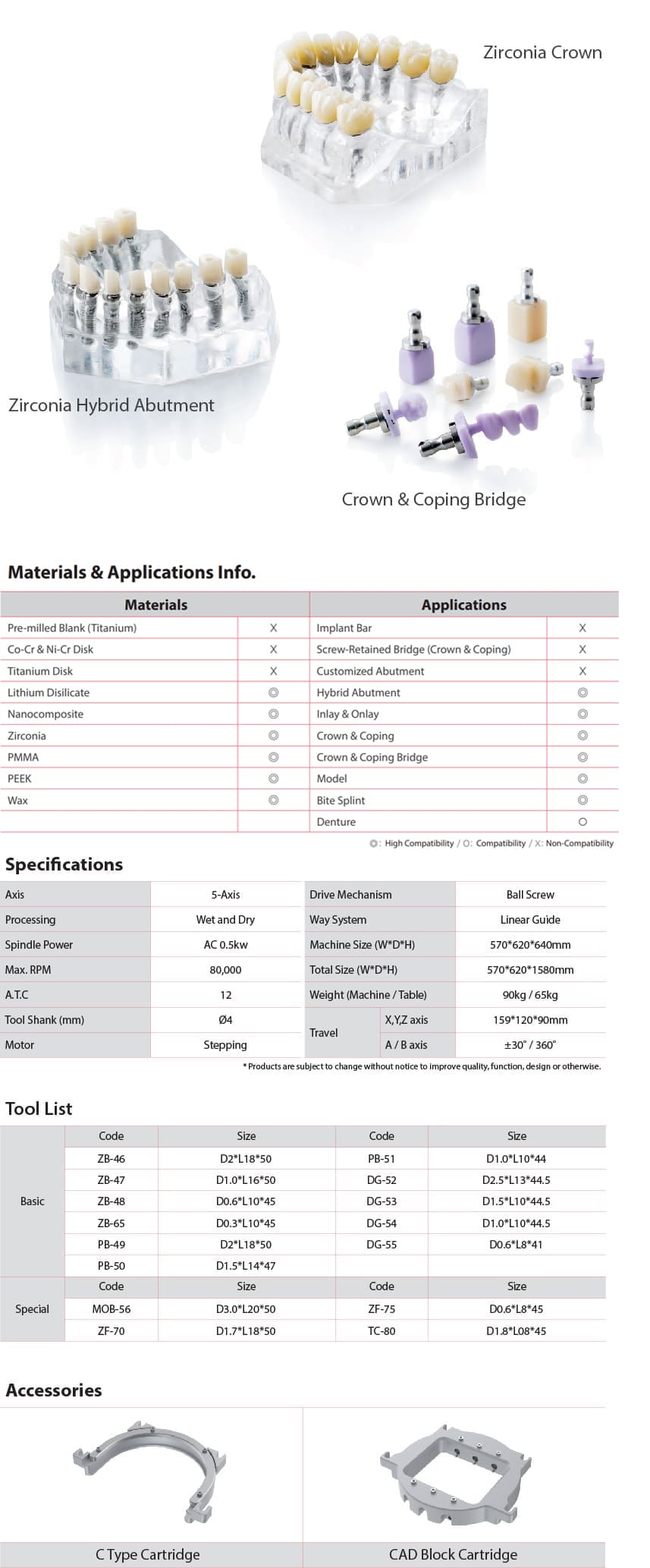

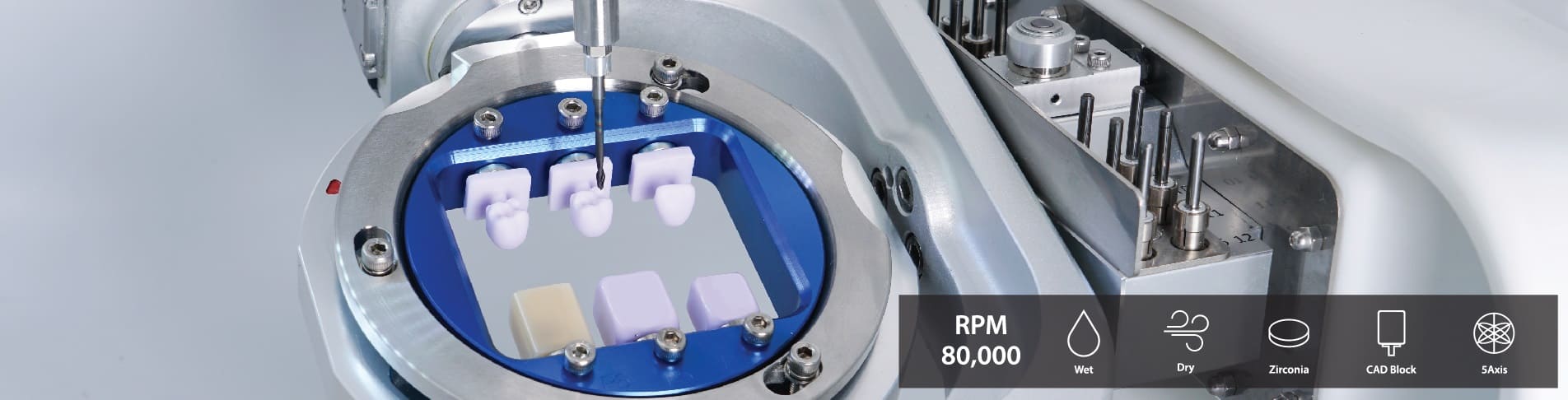

5X-300 Pro

Efficient C-TYPE JIG

Labial (or Buccal) side texture and undercut area precision processing minimize post-processing time.

Easy material change

You can easily exchange from disk to CAD block as it uses cartridge type materials.

All in One System

An external compressor is not required, and all additional devices (Dust Collector, Coolant System) are built inside the table to overcome installation space constraint and minimize noise. ** German Renfert SILENT compact CAM model is used (optional)

Excellent detail expression

Through groove, labial side texture precision processing using ARUM's exclusive 0.3mm tool for Zirconia, you can process prostheses close to natural teeth.

High speed 80,000 RPM

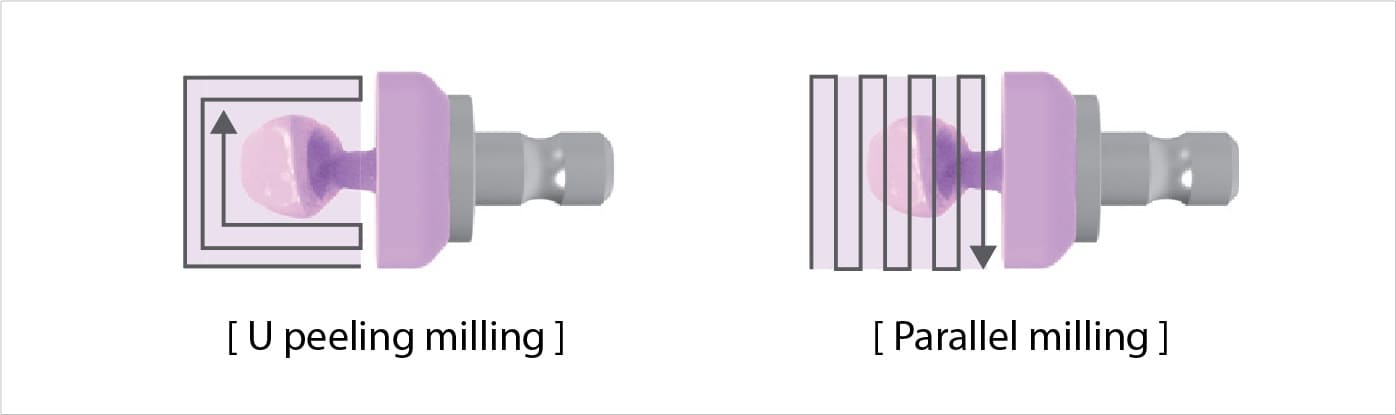

By choosing one from 2 modes of roughing process (U peeling milling, and Parallel milling), you can process glass ceramic materials more effectively.

↑ Scroll back to Milling Machine lineup ↑

ARUM DENTISTRY – Innovating Digital Dentistry

ARUM DENTISTRY Co., Ltd. specializes in the research, development and manufacture of dental CAD/CAM milling machine in the dental industry.

Founded in 2000, ARUM DENTISTRY Co., Ltd. became the first company in the same industry that has successfully developed Customized Abutment using Pre-milled Blank and launched 5X-200, a CAD/CAM milling machine, in the dental market for metal milling machine.

ARUM DENTISTRY Co., Ltd. has established the largest library and dental material line-up in the dental market in response to worldwide CAD/CAM machining cases over many years. Through full-scale inspection of all dental materials and the acquisition of approval from KGMP, FDA, CE, etc.

ARUM DENTISTRY Co., Ltd. has established the largest library and dental material line-up in the dental market in response to worldwide CAD/CAM machining cases over many years. Through full-scale inspection of all dental materials and the acquisition of approval from KGMP, FDA, CE, etc.

ARUM DENTISTRY Co., Ltd. is also building the unique competitiveness of ARUM DENTISTRY Co., Ltd. based on quality management, prompt and accurate customer support and after sales services.

ARUM DENTISTRY Co.,Ltd. always listens to the voice of our customers and continuously researches and develops advanced technologies to lead Digital Dentistry Innovation.

34028, 44, Techno 8-ro, Yuseong-gu, Daejeon, Republic of Korea

E-mail. info@arumdentistry.com Tel. +82-42-935-3644 #1 Fax. +82-42-935-3645 www.arumdentistry.com