CS Mill 5X – Dry-Type Milling Machine

About CS Mill 5X

- 5-axis simultaneous machining.

- HF Spindle 60,000 rpm (Made in Germany)

- Optimized milling template with hyperDENT® CAM software

- Intuitive & user-friendly interface

- Optimized for Zirconia / Hybrid-ceramic / PMMA / Wax

- 12 Automatic Tool Changer (HD 0.2mm Tool)

Technical Specifications

| Number of axes / Machining type | 5-Axis / Simultaneous machining |

| Spindle angle | A : ± 360° / B : ± 30° |

| Repeating precision | ± 0.003 mm |

| Drive system | Linear axes (X/Y/Z) : High Precision B/S, LM guide Rotary axes (A/B) : Harmonic Drive |

| Applicable materials | Zirconia Hybrid-ceramic PMMA Wax |

| Block size | 98.0 mm / 98.5 mm |

| CAM Software | hyperDENT® |

| Maximum feed-rate | 15,000 mm/min |

| Maximum spindle speed | HF Spindle 60,000 rpm |

| ATC (Automatic Tool Changer) | 12 ea |

| Voltage / Frequency | 100V - 240V, 50/60Hz |

| Width x Depth x Height | Milling machine : 525 x 600 x 530 mm Desk* for machine : 550 x 730 x 960 mm |

| Total weight | Approx. 65 kg (143.3 lbs) |

* The Dust Collector and Compressor are ideally placed within the prepared desk for easy installation of the CS Mill 5X milling set.

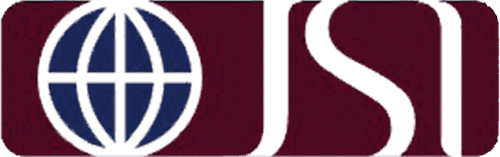

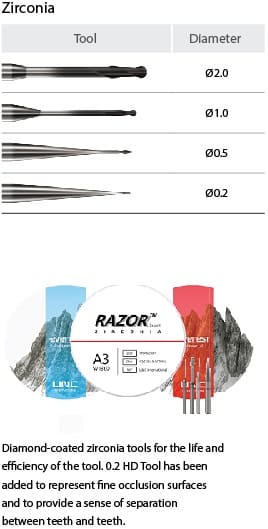

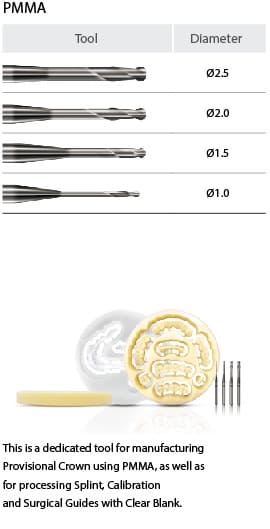

Milling Tool List

Optimized tool design for multiple materials with efficiency and safety.

12 ATC (Automatic Tool Changer), the tool is automatically selected for each material and varies the length and design of the tool to optimize milling time and machining results.

12 ATC (Automatic Tool Changer), the tool is automatically selected for each material and varies the length and design of the tool to optimize milling time and machining results.

CAM Software – hyperDENT®

hyperDENT® is the world leading software system in the dental CAM market and is valued among experts for its modular product structure. Our customers are provided with CAM solutions tailored to their specific application and implementation needs.

- Open, highly automated and flexible system

- Complete production process coverage with a single CAM software

- Simple, intuitive operation

- Maximum precision and time efficiency throughout the entire process

- Material-independent

- Flexible addition of software modules

- Maximum freedom in creating templates

- Additive manufacturing and milling all-in-one

- Automatic material offset for post milling during the hybrid process

- Automatic part identification using ID tags

- Optimum surface finish quality due to proven tool path calculation

- Consistent software enhancement and development

- Worldwide premium support service

Visit the official page for hyperDENT® here

About Caredent

Company Name: Caredent Korea Co.,Ltd

Company Name: Caredent Korea Co.,Ltd

Head Quarter / Production: 11F, 234 Beotkkot-ro, Geumcheon-gu, Seoul, Korea

Seoul T. +82-2-3443-8959

Busan Branch: 703, 257 Haeundaehaebyeon-ro, Haeundae-gu, Busan, Korea

Busan T. +82-51-987-8959

Website: www.caredent.co.kr

Customer Service Email: marketing@caredent.co.kr

Facebook: www.facebook.com/caredentkorea